Now if you go to the scene of stone renovation, a large part of the project is made of crystalline powder. Therefore, crystal powder is also the first choice for stone renovation projects.

However, good products also need to match the progress of the use of technology in order to get the best application effect. In the use of crystalline powder, there is a very important detail that directly affects the efficiency and quality of the work. But few people understand why. In this issue, we will share it.

The role of crystalline powder

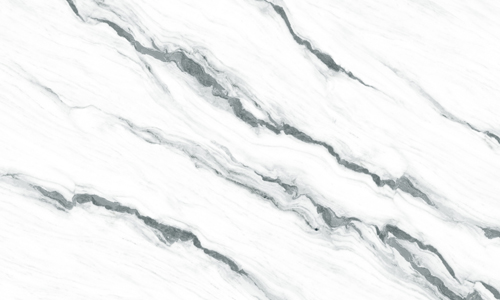

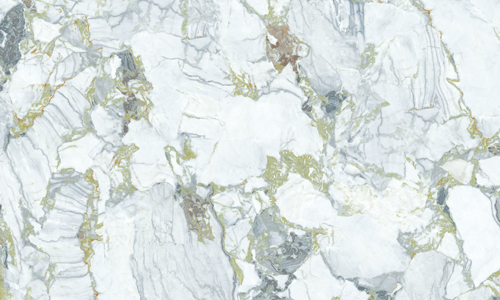

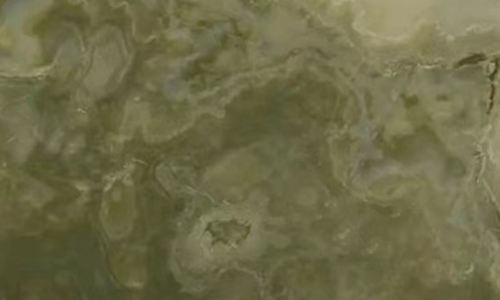

Marble crystal powder is a special crystal surface care product for marble, mainly the use of crystal surface treatment agent plus a heavy processor on the stone surface of a friction, in the chemical and physical action of dual treatment, so that the ground to form a hard and dense crystal layer, so that the stone surface is not vulnerable to damage, and not contaminated with stains, to ensure the essential characteristics of the stone.

1. The stone that has been used stone crystal powder has the original natural color of a stone on the surface, and the overall uniform and clear, like a mirror. And the hardness of the stone will also be increased, not easy to be scratched by a hard object, causing wear to the stone.

2. Stone crystal powder is modulated by a variety of nanomaterials, used in stone care will have a double chemical reaction, but also can make the stone add brightness, strengthen hardness, and have the role of anti-slip and protection.

3. The use of stone crystal powder can effectively deal with various problems presented by stone, but also extend the service life of stone, and stone crystal powder effect is good, affordable, can prevent us from changing the trouble of stone.

4. Stone crystal powder is mainly the maintenance of marble, stone treated by stone crystal powder, the surface will become full color, crystal clear, gloss reached more than 95 degrees, just like the new factory stone.

5. After the stone crystal powder treatment, the hardness of the stone is significantly improved, and it is also very wear-resistant, and will not fade leisurely, the surface is uniform, flat, smooth, like a mirror, and will not absorb dust, which is better for our daily liquidation.

Improper use of crystal powder, where does the problem come from?

1.Uneven distribution: first water, then powder, machine pressure. Move the machine again and again to spread the powder evenly. In fact, the process of dispersing alone takes a long time, and it may not be able to disperse evenly. Don't believe that we can press the handle up, the mat on the powder, a lot of places are already clumping.

2.Weaken the etching effect: As previously said, the acid ions in the powder need to be fully dissolved, with the water covered to the stone surface and penetrate the shallow surface, in order to react with the stone calcium. But if you pour water in advance. Water first infiltrates the stone, and then puts powder, one is that the acidic component is not fully dissolved. Second, the stone has sucked up water, acid ions and then infiltrate the stone, the efficiency will be greatly reduced. In short, the important etching effect is greatly weakened.

3.Local ablation: the crystal powder is insufficiently dissolved, and the local action is violent and weak around it. The area where the crystal powder is concentrated will easily cause ablation.

4.Uneven filling: It is also caused by inadequate dissolution of filling ingredients and uneven distribution.

In summary: Due to the above reasons, the practice of grasping a handful and still makes the three principles of crystallization powder can not be well realized. When operating, it will be tossed around for a long time without effect. At the same time, due to the uneven etching and filling effect, it is easy to appear local ablation whiteness, and the overall dddhhhfoggydddhhh effect. This completely loses the core advantage of dddhhhefficient light productiondddhhh of crystalline powder.

The correct use of crystal powder: add water first

Let's take a single disk machine to do powder as an example:

1. First choose the appropriate area: As mentioned earlier, the action process of crystalline powder, acid etching, grinding optimization, and filling are complementary and indispensable. So when we make powder, we have to complete all the operations in the appropriate time. And can not let the acid etching reaction is finished, and then go up with the mat to do grinding and filling, the effect is definitely not good. Therefore, when doing powder, you should choose 2 to 3 square meters each time, and the maximum is not more than 5 square meters. In general, within an area of 2 to 5 square meters, choose according to your own habits. Then add water to the corresponding amount of powder according to the area.

2. The use of crystal powder: (1) First of all, clean all kinds of stains on the surface of the stone, and then use the absorption machine to clean the residue on the surface.(2) And then put the stone crystal powder on the surface of the stone, according to the ratio of 1:6 mixing, with the stone crystal surface machine with the white cleaning pad, according to the material of the stone to the top time, and then wash with water gently, with the water suction machine until dried.(3) Take some stone crystal powder and water to paste, and then use the stone crystal surface machine with fiber pad grinding, know to dry the ground.(4) Finally check the stone crystal layer brightness and oil moisture is not satisfied, if the satisfactory approach surface is reached, it can be used directly when doing renovation projects.(5) Wait until the ground is dry, and then push the dust with clean dust.(6) In addition, with the use of tune is also very important, that is, adjust the amount of 2 to 5 square, immediately use. Adjust it when you're done. Instead of filling a VAT with water and waiting to be used. After all, crystallizing powder is different from crystallizing agent, in which the composition of the water is dissolved, the effect will decay with time.

3. Polishing skills:

(1) back and forth 3 times, horizontal and vertical cross.

Like all polishing materials, crystallizing powder should also be uniform and fine, and formed at a time. The correct approach is to start polishing along the edge of the rectangle in a rectangular area of 2 to 5 square meters. With the diameter of the grinding disc of the crystal surface machine as the width, it goes back and forth 3 times horizontally, that is, dddhhhleft → right → leftdddhhh or dddhhhright → left → rightdddhhh after grinding. Then pull down half the millstone again and continue dddhhhleft → right → leftdddhhh or dddhhhRight → left → rightdddhhh. Until the entire 2 to 5 square area is thrown sideways. Then replace it with a vertical toss, which is also three times back and forth, and press half the mill. Until the entire area is thrown horizontally and vertically, you can make an excellent finished effect. The time comes up, and the area of 2 to 5 square meters takes 2 to 5 minutes. In simple terms, it is the next one to press half of the last one.

(2) The powder moves no more than 3 times.

After finishing polishing in one area, the residual powder can be moved to the next area with the scraper of the pump, and the adjusted powder can be added to continue polishing. Note: When the newly added powder is adjusted, the ratio of powder should be more appropriate to adjust the concentration of residual powder. Splash it on and spread it quickly with the scraper.

However, it should be noted that the use of this residual powder has reached the limit of use by moving 2 to 3 times. It is generally found that a lot of foam is produced when the powder is thrown, indicating that the reaction of the active ingredient has completely ended. I need to vacuum it out. I can't use it anymore.

(3) After the overall disposal, pay attention to cleaning up residual substances.

After the whole is done, there is still powder residue on the surface, and it will continue to react. If it is not cleaned up in time, the newly made surface may be re-ablated and lose light. The cleaning methods are: Method 1: Use an automatic floor washing machine to clean the whole thing once. Method 2: Use a single plate machine + clean and dry cleaning pad, the surface material can be cleaned. Method 3: At least use clean dust to push and clean up the surface material.

(4) If the local stone has been ablated white, how to do?

Encounter this phenomenon, in the white area, use 1000# grinding piece to grind it, and then re-throw powder.

About Us

Jessie

Fortune East Stone

📧 Email: sales08@fortunestone.cn

📞 Phone: +86 15880261993

🌐 Websites: www.festonegallery.com | www.fortuneeaststone.com